How are Stainless Steel Kitchen Utensils Made?

Creating a stainless steel kitchen utensil is a fascinating process that combines modern technology with traditional craftsmanship. At SHUANGYI, every stage of the process requires significant attention to detail and care, as they play a significant role in shaping the quality, durability, and aesthetics of our stainless steel kitchen utensils. Today, let’s learn how are kitchen utensils made!

STEP 1: Steel Cutting

We start the process with steel-cutting. Large sheets of stainless steel are cut into smaller pieces for subsequent forming processes. This process requires precision to ensure each piece is cut to the exact size needed for the specific utensil being made.

STEP 2: Shape Cutting

Next, we move on to shape cutting. The smaller pieces of steel are cut into the rough shape of the final product. This could be the basic outline of a soup ladle, spatula, cooking spoon, or any other kitchen utensil.

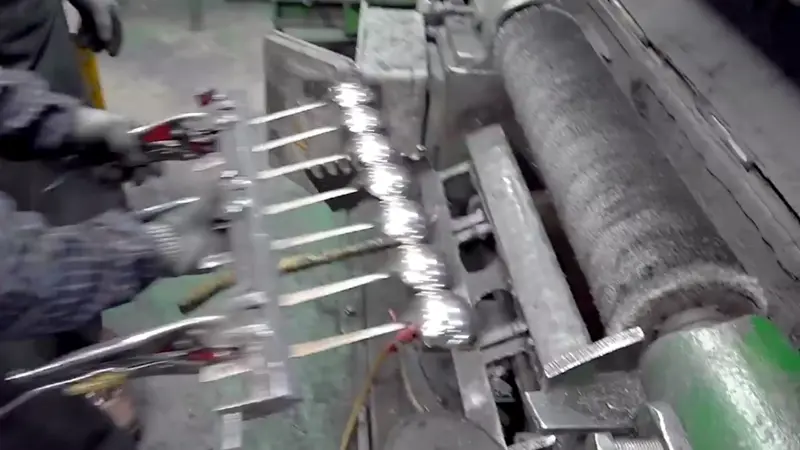

STEP 3: Rolling

The shaped steel pieces then go through a rolling process. They are passed through high-pressure rollers to make them thinner and to smooth out any rough edges. This process also hardens the steel, making it more durable.

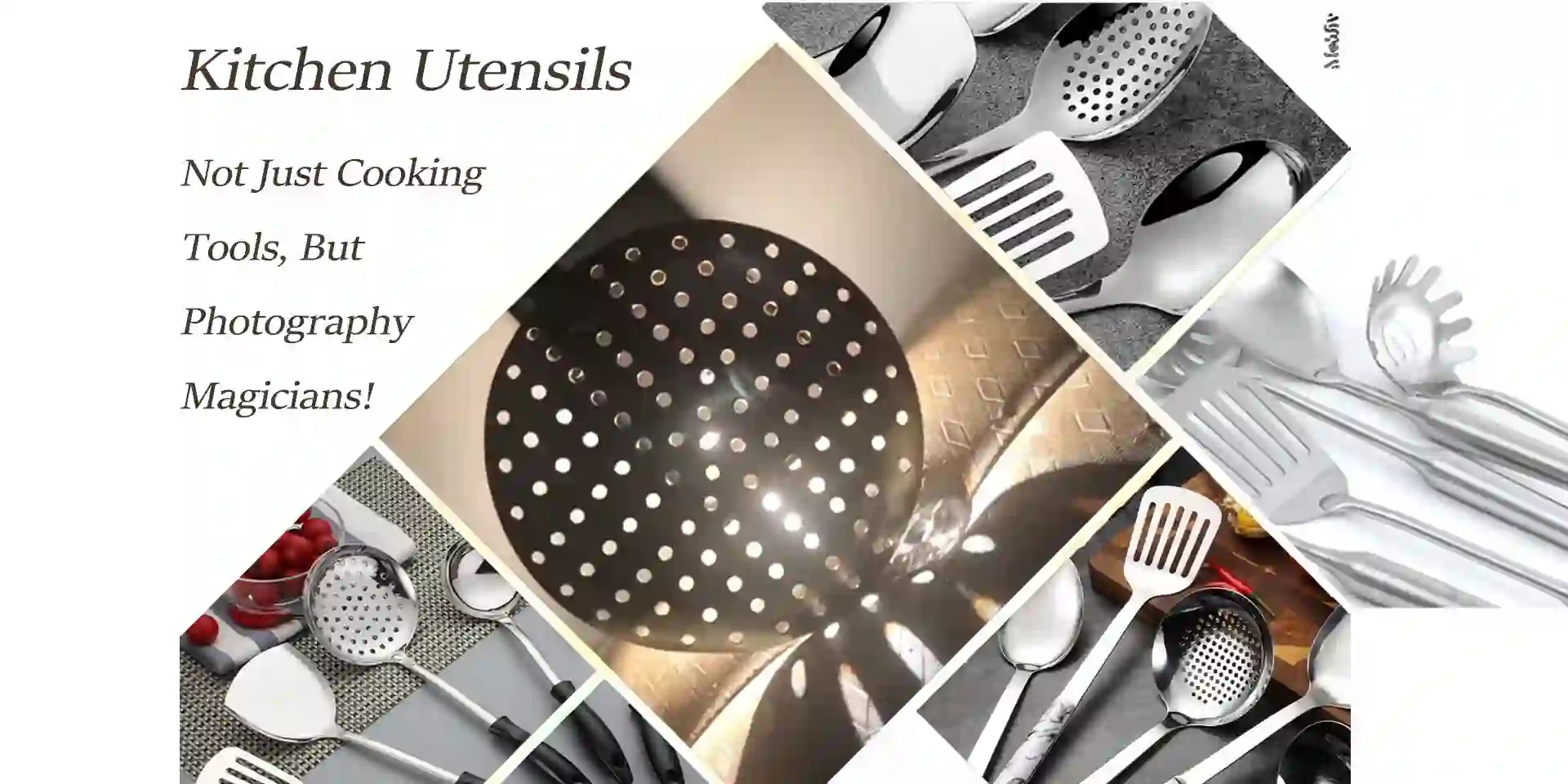

STEP 4: Forming and Stamping

Here’s where the magic happens! The rolled steel pieces are formed into the recognizable shapes of soup ladle, slotted spatula, cooking spoon, and other kitchen essentials. This involves bending them into their final shape after multi-step processes and stamping them with any necessary markings, such as the brand name or the type of steel used.

STEP 5: Edging

Then the utensils go through an edging process. This involves smoothing out the edges of the utensils to ensure they are safe to use and comfortable to hold.

STEP 6: Polishing and Finishing

Next, the utensils are buffed to a high shine and coated with a protective finish. This not only makes the utensils look attractive but also helps to prevent rust and prolong their lifespan.

STEP 7: Quality Inspection

Finally, conduct strict quality inspection on the manufactured stainless steel kitchenware products, including visual inspection, dimensional measurement, and functional testing, to ensure compliance with relevant standards and specifications.

Commitment to Sustainability

Throughout the production process at SHUANGYI, environmental protection measures are embedded in every stage. Here are crucial ways we integrate eco-friendly practices to minimize our ecological footprint.

- Energy-Efficient Manufacturing Equipment: We utilize advanced, energy-saving machinery to ensure our operations are as efficient as possible.

- Waste Reduction Strategies: Our processes are designed to minimize waste and optimize the use of resources.

- Sustainable Material Sourcing: We carefully select materials that are sustainably sourced and environmentally responsible.

- Recycling and Reusing in Production: We prioritize recycling and reusing materials to further decrease our environmental impact.

By choosing SHUANGYI, you’re collaborating with a company dedicated to reducing environmental impact without compromising on product quality.